So I received the new cover plate from Van's and followed the same procedures in the previous posts to sraw a new center line on the cover plate that basically centers the output shaft of the servo arm with the center of the access hole in the plate and the elevator. In short, the line was moved barely an eighth of an inch or so from where it was.

Here I have attached the cover plate to the elevator and placed my straight edge/ruler over the slots where the center point is. I just roughly estimated where center was, and made a mark on both sides and drew the line.

Next I centered up the trim tab on the elevator and took my straight edge and extended it from the new line on the cover plate down to the control horn. Now you can see that the horn is displaced off to one side of the horn, just as I had expected.

Next is transferring the line from the top of the cover plate to the bottom. I also deburred and dimpled the cover plate, including the edges:

Not sure why this pic still appears to show that the arm is still a bit off center from the slot in the plate. It really was not. Anyway this gives you an idea of the clearance of the clevis pin to each side of the plate. In actuality it will be a bit different because there are two washers that are placed on both sides of the clevis pin during final assembly.

And here we are all clecoed together and clamped to the drawing for final positioning and drilling the mounting bracket holes to the cover plate.

Oh yeah, I did also draw another outline of the cover plate on my cardboard template. Here you can see the difference in the original line that I drew and the new one which is now centered with the slot on the plate. I did not notice the reflection on the bottom of this pic until just now. I was holding the card board against the top of the elevator skin. Amazing - even after all the finger prints and dings and scratches on the skin, it still acts like a mirror! So, just focus on the upper two thirds of the photo. Sorry for the illusion...

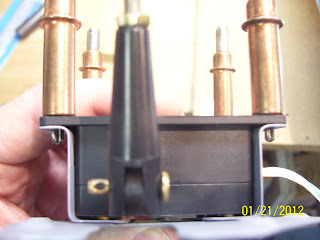

These next two shots attempt to show the clearance of the clevis and control arm of the servo against the cover plate when the arm is fully extended.

What this confirms is that even when the arm is fully extended there is still adequate clearance of the clevis pin and clevis with the cover plate. The only other concern at this point will be the clearance of the cotter pin that is inserted into the clevis pin to keep everything attached and secure.

Here are the mounting brackets after removing the cardboard template, reclamped back onto the drill board. I once again traced the outline of the mounting brackets to ensure that they remain correctly aligned when I drill the rivet holes to #40 through the cover plate.

And here are the first 4 holes drilled and clecoed directly to the drill board. The last two holes extend beyond the drill board and I simply went ahead and drilled those as well in the overhanging position.

And finally checking the alignment of the threaded rod from the servo out to the control horn of the trim tab. Slightly off to one side, just as I had expected. What I have not shown is that I used Gorilla duct tape strips to hold the trim servo to the mounting brackets and keep the servo wires from getting crimped while I installed the servo in the elevator. There are screws and lock nuts to attach the trim servo to the mounting brackets, but those lock nuts are stiff as hell, and I did not want to permanently afix the servo to the mounting brackets just yet, so I used the tape.

The access hole, although appearing to be quite spacious when viewed by itself, is actually only just large enough to insert the cover plate-trim servo assembly into the elevator. You have to find the special method to twist and turn it just right so that it will fit into the hole. You also have to remember to position the servo arm so that it allows enough clearance to insert or remove the assembly. I found that centered works out pretty well. This is a note I will have to make in my maintenance procedures when I perform each annual condition inspection, or any time I need to service that part of the plane.

I don't know if others end up grinding down their nut plate flanges to align with the edges of the elevator skin around the access hole, but after fiddling with trying to get the servo inserted into the elevator, I don't see how you can get the mounted servo in there without doing exactly that. That is how closely matched the hole dimensions are to the cover plate assembly.

Pretty much centered through the hole, but what about the offset of the control horn? Now back to the great debate - bend the rod or don't bend the rod. So I called the Ray Allen company and spoke to one of Ray's sons that now runs the company. Had a very nice conversation with him and learned that this company has it's roots from associations with Jim Kraft, maker of the Kraft radio control systems that were widely used in the 60s and 70s, right about the same time I was becoming interested in the hobby. In fact, my neighbor Kevin and his wife Mary stopped by while I was in the garage the other night to check on my progress. When Kevin saw the servo (he is also an RC enthusiast) his first comment was " gee, that looks just like a big RC servo." He is absolutely correct, but it is a heavy duty servo compared to the smaller ones that are designed for use in RC airplanes, but they all are basically designed to do the same thing.

Anyway. The main reason for the call was to detemine what to do with the Rod. I was told that he had looked at many many RV6s and other airplanes that had been out in the field for quite some time now, and he had never seens signs of the hole in the control horn warbeling or being worn away due to stresses of non alignment of the rod with the horn. Based on that, he said they don't recommend putting any bends in the rod, and his advise was just to mount everything up and check it, and then monitor it after the flying begins. I told him that I also noticed that the two part horn assembly tends to separate at the tip just a bit where the holes for the clevis pin are located, but when I apply force to the rod to move the trim tab it actually brings the horns closer together, which is good.

So maybe it will be fine "as is" with no bending of the rod. If you look closely at the plans from Vans, they also show the trim servo assembly with the one side of the wide clevis butted up tight to one side of the trim tab control horn. This leaves a very large gap of the other side of the clevis. I was always taught to aim for the mid point of anything that has any play to one side or the other, for reasons similar to learning how to land a plane on the center line of the runway. You keep it on the center line so that if anything should happen such as a blown tire, locked up brake, or gust of wind, or anything that might induce a side load to the object, you still have some margin of runway on either side of the center line to keep from running off the runway surface. Or in this case, from running into either edge of the control horn, which would create wear over time. Oh well - that's the way that Van's shows it in the plans, and with over 7500 of them flying out there, I guess I will follow suit.

In fact, he even asked me if the horn was still designed such that it is just two pieces of thin .020 aluminum connected together. I told him yes it was. He asked me because the width of the opening in the clevis that slides over both sides of the hole in the control horn is at least 3/8 inches wide, much wider than the thickness of the two control horn pieces. I was even wondering if we needed to insert a bearing of some sort to remove the gap, but I guess not.

Then we talked about the new trim tab assembly on the new Cessna Skycatcher, which is also apparently using one of their (Ray Allen) control assemblies. He commented about how beefy, ugly, and overbuilt that trim tab was. So I think it's kind of funny, on the one hand you have an overbuilt assembly for a production aircraft, and then on the other hand you have the "just good enough" approach that Van's is using. As long as there is no binding during movement of the tab, then it should be fine.

Here is a final pic of the rod as it exits the slot. Note the original mark on the top where the old rod centerline was located, compared to the centered location now. Whew, now that that is over, on to the next thing, which is to cut the rod to te proper length. SO this gave rise to another question to Ray Allen. How far do you screw in the rod to each clevis? He told me that the MINIMUM is only 3 turns on to each clevis. Apparently they have conducted tests where he told me that it took 400 pounds of pressure to separate the clevis from the rod with it attached by only three turns on each end. WOW! The trim servo itself is only designed to handle about 40 pounds of force. This means that inserting more thread into the clevis is a plus for strength.

In my RC days there was a standard practice to take the 1/16 inch threaded rods we use in the hobby and screw them all the way into the shaft of the nylon clevis, and add another 1/16 inch of threads as a safety factor and to allow for adjustments. This typically ended up being about 3/4 of an inch of thread inserted into the clevis. I can only manage to screw in the rod for this assembly about the same amount - about 3/4 inches, which is still way below the hole on the other end of the clevis. Apparently this is more than adequate enough. This also seems to be about the length shown in the plans from Vans, if you adjust for the scale of the drawing, which brings up another thing.

I searched long and hard on VAF to find posts that deal with the correct length to cut the rod, which is not mentioned anywhere in the plans. All you get is the drawing at 3/8 scale with no notes about this at all. This turns out to be a common practice with most of Vans full sized plans. Many drawings of subassemblies are set to 3/8 scale. I have found that there are many times that I want to determine the actual measurements from the scale drawings, and so in order to do this you have to know how to convert from smaller scale to actual size, and sometimes you need to go in reverse from actual size down to 3/8 or some other scale.

Anyway, after hours of searching I could not find anything that gave me the answers I was looking for. Some people made a reference to 3 3/8 inches, saying that this is what Vans recommends. But as I said, I could not find reference to that measurement anywhere in the plans. Finally I found one post with only two entries from 2007, and they basically said that they just estimated the length and cut it. Perhaps the plans were different back then, I don't know, but being an avid RC scale enthusiast for a long time, I was just not satisfied with the "esitmate and cut" approach to this. So I reopened this thread with a post that describes the detailed process to perform the mathematical conversion from the 3/8 scale drawing in the plans to reveal the approximate actual length of rod that should be cut. You can see my solution

here.

'Nuff for now. Gonna go out with the rest of the Denver RV List crew to have dinner and see the new Red Tails movie tonight. Should be loads of fun. In the mean time, I have a 3 5/8 inch long piece of rod to cut, which is the length that I determined needs to be cut per the steps in the post. This leaves about 3/4 inches of rod in each clevis, and allows for the correct length between the servo arm and the control horn of the trim tab. Initial dry measurements of this length appear to be correct for my installation. Proof enough for me that the scale conversion method works, and takes the guess work out of the process.